maintenance on case910 skid steer The first step to replace the hydraulic cylinder on a skid steer grapple is to remove the old one. Follow these instructions to successfully take the previous cylinder off the skid steer: Locate the hydraulic cylinder on the grapple. Inspect it for mounting bolts and hydraulic lines. . The Bobcat E88 is a powerful and versatile compact excavator with up to 14 percent more over-the-side lift capacity than the previous generation. It features a Tier 4 turbo diesel engine, a spacious cab, a touch display and various upgrade options.

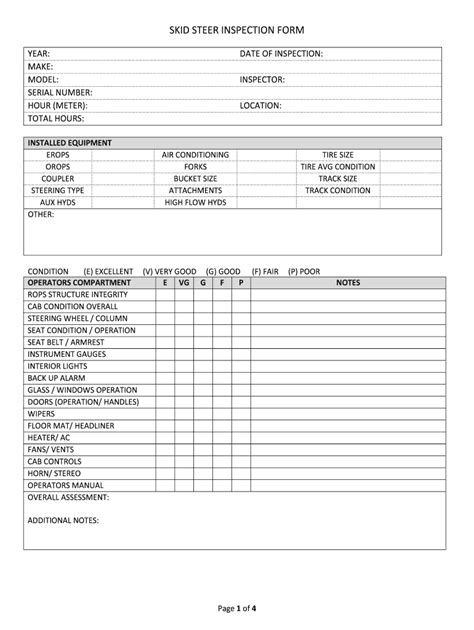

0 · skid steering maintenance checklist

1 · skid steer repair checklist

2 · skid steer maintenance schedule

3 · skid steer maintenance plan

4 · skid steer maintenance guide

5 · cat skid steer maintenance guide

6 · cat skid steer loader maintenance

Find mini excavators for rent from 2,000 to 18,000 lbs. for your confined jobsites. Learn how to operate, dig and backfill with mini excavators from trusted manufacturers like Bobcat and Takeuchi.

The first step to replace the hydraulic cylinder on a skid steer grapple is to remove the old one. Follow these instructions to successfully take the previous cylinder off the skid steer: Locate the hydraulic cylinder on the grapple. Inspect it for mounting bolts and hydraulic lines. . The first step to replace the hydraulic cylinder on a skid steer grapple is to remove the old one. Follow these instructions to successfully take the previous cylinder off the skid steer: Locate the hydraulic cylinder on the grapple. Inspect it for mounting bolts and hydraulic lines. Carefully disconnect the hydraulic lines using a wrench.

To establish a preventive maintenance program, start by creating a maintenance checklist tailored to your skid steer’s specific requirements. Set up a regular schedule for inspections, fluid changes, filter replacements, and other maintenance tasks.

14x17.5 skid steer rims

1. Check for Visible Damage and Replace Worn Parts. Before you hop in the cabin, check your skid steer for visible damage. Inspect the tires, bolts, hoses, fuel tanks, boom and body for cracks or other signs of damage. Pay special attention to weld sites. 2. Remove Debris From the Attachments.Daily maintenance keeps your machine running at peak performance. See what you need to do to maintain your new skid steer loader. In this Shop Talk blog post, we’ll discuss the key maintenance tasks for skid steer final drives that will increase their uptime, reduce repair costs, and extend their lifespan.Learn how to maintain your skid steer loader with daily, monthly and yearly inspections, fluid levels, attachments and more. Wheeler Machinery offers Cat ® maintenance schedules and genuine parts to keep your equipment running at peak performance.

If you want more uptime, lower overall operating costs, greater resale value, and a longer life for your skid steer, preventive maintenance (PM) is key. Experts from CONEXPO-CON/AGG staples Caterpillar, CASE and Wacker Neuson have all the PM maintenance tips you need for skid steers.

skid steering maintenance checklist

If you want more uptime, lower overall operating costs, greater resale value, and a longer life for your skid steer, preventive maintenance (PM) is key. Experts from Caterpillar, Case, and Wacker Neuson have all the PM maintenance tips you need for skid steers.Proper maintenance is key to get the most out of your Cat® D3 series Skid Steer Loader or Compact Track Loader. This video reviews the basic daily maintenance steps you should take to keep your machine in top working condition.

One of the best ways to make sure your skid steer or compact track loader is in good shape is to stick to a regular maintenance schedule. With scheduled maintenance, you can lower your overall maintenance costs by avoiding more expensive repairs . The first step to replace the hydraulic cylinder on a skid steer grapple is to remove the old one. Follow these instructions to successfully take the previous cylinder off the skid steer: Locate the hydraulic cylinder on the grapple. Inspect it for mounting bolts and hydraulic lines. Carefully disconnect the hydraulic lines using a wrench.

To establish a preventive maintenance program, start by creating a maintenance checklist tailored to your skid steer’s specific requirements. Set up a regular schedule for inspections, fluid changes, filter replacements, and other maintenance tasks.

1. Check for Visible Damage and Replace Worn Parts. Before you hop in the cabin, check your skid steer for visible damage. Inspect the tires, bolts, hoses, fuel tanks, boom and body for cracks or other signs of damage. Pay special attention to weld sites. 2. Remove Debris From the Attachments.Daily maintenance keeps your machine running at peak performance. See what you need to do to maintain your new skid steer loader.

In this Shop Talk blog post, we’ll discuss the key maintenance tasks for skid steer final drives that will increase their uptime, reduce repair costs, and extend their lifespan.

Learn how to maintain your skid steer loader with daily, monthly and yearly inspections, fluid levels, attachments and more. Wheeler Machinery offers Cat ® maintenance schedules and genuine parts to keep your equipment running at peak performance. If you want more uptime, lower overall operating costs, greater resale value, and a longer life for your skid steer, preventive maintenance (PM) is key. Experts from CONEXPO-CON/AGG staples Caterpillar, CASE and Wacker Neuson have all the PM maintenance tips you need for skid steers. If you want more uptime, lower overall operating costs, greater resale value, and a longer life for your skid steer, preventive maintenance (PM) is key. Experts from Caterpillar, Case, and Wacker Neuson have all the PM maintenance tips you need for skid steers.

Proper maintenance is key to get the most out of your Cat® D3 series Skid Steer Loader or Compact Track Loader. This video reviews the basic daily maintenance steps you should take to keep your machine in top working condition.

18 inch sand auger skid steer

skid steer repair checklist

skid steer maintenance schedule

18 inch skid steer tires

skid steer maintenance plan

Learn how the next generation of Cat mini excavators are designed to meet your needs for performance, comfort, control and service. See how customers like Samuel Portaud use them for vineyard work and enjoy the stick steer, air conditioning and cruise control options.

maintenance on case910 skid steer|skid steer maintenance guide