skid steer pinch points The Koehring Company conducted tests on skid steer loaders which suggest that under certain . Kindno Track is one of the leading suppliers of rubber tracks for mini diggers and excavators, offering high quality rubber tracks at low costs with long life and self-cleaning technology.Tonly is one of the most professional excavator rubber tracks manufacturers and suppliers in China since 1958. Welcome to wholesale bulk excavator rubber tracks for sale here and get quotation from our factory. All customized .

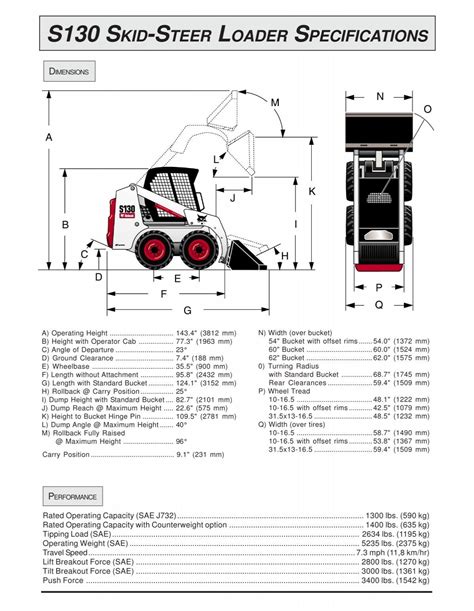

0 · skid steer loader specifications

1 · skid steer loader safety checklist

2 · skid steer loader requirements

3 · skid steer loader best practices

4 · skid steer loader

China Excavator Parts wholesale - Select 2024 high quality Excavator Parts products in best price from certified Chinese Excavator manufacturers, Plastic Part suppliers, wholesalers and factory on Made-in-China.com

skid steer loader specifications

The Koehring Company conducted tests on skid steer loaders which suggest that under certain .Employees' Exposure to Possible Pinch Point Hazard on Certain Models of Bobcat Skid-Steer .

skid steer loader safety checklist

When working with skid-steer loaders, workplace environmental risks include the material-handling method; pinch-point actions; overhead moving/falling objects; work surfaces; facility and work-site layout conditions; weather conditions; catch points; puncture, shear-point and flying-object actions; illumination; and sound level.

The Koehring Company conducted tests on skid steer loaders which suggest that under certain circumstances it is possible for an operator, by improper use of the pedals, to defeat the function of the safety bar. This may occur if the pedals are depressed immediately before the .

Employees' Exposure to Possible Pinch Point Hazard on Certain Models of Bobcat Skid-Steer Loaders Equipped with Either Loader or Backhoe Attachments Manufactured by the Melroe Company. (August 6, 1993).

Letter of Interpretation - Pinch Point hazards on skid steer loaders w/backhoe. OREGON OCCUPATIONAL SAFETY AND HEALTH DIVISION DEPARTMENT OF CONSUMER & BSIENSS SERVICES. SUBJECT: Employee exposure to potential pinch poing hazards on skid steer loaders equipped with backhoe attachments.

Pinch points, shear points, and crush points exist within close reach of the operator’s space. See Task Sheet 3.1, Mechanical Hazards, to review pinch point, shear point, and crush point hazards. Figure 6.1.a. Skid steers are controlled by hand levers or joy sticks. Push the levers forward to travel forward; pull back to go in reverse.Pinch points, shear points, and crush points exist within close reach of the operator’s space. See Task Sheet 3.1, Mechanical Hazards, to review pinch point, shear point, and crush point hazards. Figure 6.1.a. Skid steers are controlled by hand levers or joy sticks. Push the levers forward to travel forward; pull back to go in reverse.

Learn how to operate and maintain skid-steer loaders safely to prevent accidents and injuries. This fact sheet covers pre-start inspection, entering and start-up, operation, and emergency procedures.

skid steer loader requirements

Know the pinch points and avoid them! Inadvertent bumping of controls can result in instant lowering of lift arms. When traveling. Keep the bucket low. If vision is blocked, travel backwards. Slow travel keeps the machine under control. • Pinch points are common on skid steers and can easily lead to injuries to body parts. BEST PRACTICES FOR SAFELY OPERATING SKID STEER LOADERS • Always adhere to the manufacturer’s guidelines for operation. Never operate a skid steer without proper training. • Do not work under the raised arms or bucket of a skid steer, even if it is off.Skid steers are a common and critical piece of equipment on the farm. With moving buckets, blind spots, and varying center of balance, these machines can be dangerous to operators and bystanders despite the productivity benefits. While they pose hazards like pinch points, runovers, and entrapment, safe operation is possible. When working with skid-steer loaders, workplace environmental risks include the material-handling method; pinch-point actions; overhead moving/falling objects; work surfaces; facility and work-site layout conditions; weather conditions; catch points; puncture, shear-point and flying-object actions; illumination; and sound level.

The Koehring Company conducted tests on skid steer loaders which suggest that under certain circumstances it is possible for an operator, by improper use of the pedals, to defeat the function of the safety bar. This may occur if the pedals are depressed immediately before the .Employees' Exposure to Possible Pinch Point Hazard on Certain Models of Bobcat Skid-Steer Loaders Equipped with Either Loader or Backhoe Attachments Manufactured by the Melroe Company. (August 6, 1993).Letter of Interpretation - Pinch Point hazards on skid steer loaders w/backhoe. OREGON OCCUPATIONAL SAFETY AND HEALTH DIVISION DEPARTMENT OF CONSUMER & BSIENSS SERVICES. SUBJECT: Employee exposure to potential pinch poing hazards on skid steer loaders equipped with backhoe attachments.

Pinch points, shear points, and crush points exist within close reach of the operator’s space. See Task Sheet 3.1, Mechanical Hazards, to review pinch point, shear point, and crush point hazards. Figure 6.1.a. Skid steers are controlled by hand levers or joy sticks. Push the levers forward to travel forward; pull back to go in reverse.

Pinch points, shear points, and crush points exist within close reach of the operator’s space. See Task Sheet 3.1, Mechanical Hazards, to review pinch point, shear point, and crush point hazards. Figure 6.1.a. Skid steers are controlled by hand levers or joy sticks. Push the levers forward to travel forward; pull back to go in reverse.

Learn how to operate and maintain skid-steer loaders safely to prevent accidents and injuries. This fact sheet covers pre-start inspection, entering and start-up, operation, and emergency procedures. Know the pinch points and avoid them! Inadvertent bumping of controls can result in instant lowering of lift arms. When traveling. Keep the bucket low. If vision is blocked, travel backwards. Slow travel keeps the machine under control. • Pinch points are common on skid steers and can easily lead to injuries to body parts. BEST PRACTICES FOR SAFELY OPERATING SKID STEER LOADERS • Always adhere to the manufacturer’s guidelines for operation. Never operate a skid steer without proper training. • Do not work under the raised arms or bucket of a skid steer, even if it is off.

john deere 335p compact track loader

skid steer loader best practices

skid steer loader

歡迎大家來到《四川觀察》海外官方頻道《熊貓眼Pandaeyes》,觀觀來啦~Welcome to Pandaeyes,the official overseas channel of Sichuan Watch, here comes Guan Guan .

skid steer pinch points|skid steer loader safety checklist